2024 Excavators Or Earthmoving equipment’s: What’s New in the Industry?

Excavators or Earthmoving equipment’shave evolved significantly in 2024. Technological advancements lead the change. These innovations focus on efficiency and safety. Let’s explore the key advancements.

Electric Excavators

Electric excavators or earthmoving equipment’s are acquiring popularity. They offer zero emissions. This is significant for urban regions. The noise pollution decreases altogether. Care costs are lower with electric models. Battery duration is improving quickly. Charging times are decreasing as well.

Autonomous Technology

Independent excavators or earthmoving equipment’s are now a reality. One can operate them without his/her involvement. GPS and sensors guide them accurately. This technology reduces the human errors. It also increases productivity and well-being. Remote control options are available. Workers can control an electric excavator from a distance through a small remote.

AI and Machine Learning

AI enhances excavator performance. Machine learning improves task accuracy. Excavators or earthmoving equipment’s learn from past tasks. They adapt to different terrains. Predictive maintenance is possible with AI. This reduces downtime and repair costs. Intelligent systems optimize fuel consumption.

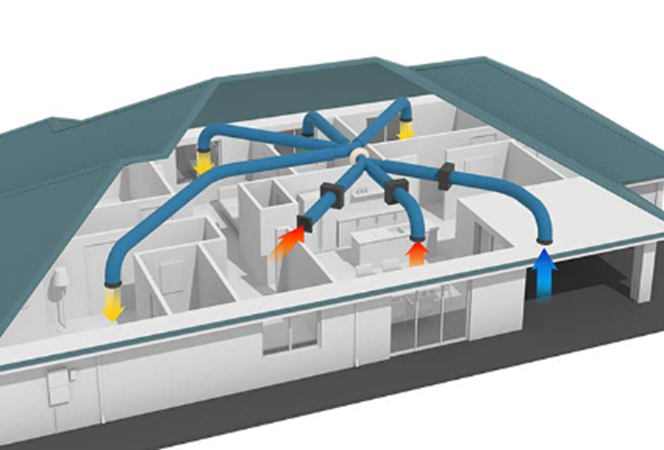

Telematics Integration

Telematics is transforming excavators or earthmoving equipment’s management. It provides real-time data. Fleet management becomes easier.We analyze usage patterns for better performance. We optimize maintenance schedules. This increases the lifespan of machines. Fuel efficiency is monitored closely.

Enhanced Safety Features

Safety is a top priority. Advanced safety features are now standard. Proximity sensors prevent collisions. Cameras provide 360-degree views. Alerts notify operators of potential dangers. We integrate automated emergency stops. We enhance safety training with virtual reality.

Hydraulic Advancements

Hydraulic systems are more efficient. They provide better control. Energy efficiency is improved significantly. New materials reduce wear and tear. Hydraulic fluid life is extended. This lowers maintenance costs.

Compact and Versatile Designs

Compact excavators or earthmoving equipment’s are more versatile. They fit into tight spaces easily. Their power remains uncompromised. You can quickly swap attachments. This increases their functionality. They are ideal for urban projects.

Environmentally Friendly Options

Sustainability is a focus. They use biodegradable hydraulic fluids. Recyclable materials are in new designs. Fuel-efficient engines reduce emissions. Solar panels power some components.

Advanced Operator Controls

We improve operator comfort. Ergonomic designs reduce fatigue. Joystick controls are more intuitive. Touchscreen interfaces are common. Voice commands are becoming popular. These advancements increase productivity.

3D Printing for Parts

3D printing is revolutionizing part production. We print replacement parts on-demand. This reduces downtime significantly. Custom parts are easily created. Costs are lower for rare parts.

Improved Digging Technologies

Digging technologies are more precise. Advanced sensors guide digging depth. Software calculates optimal digging angles. This improves efficiency and accuracy. Soil displacement is minimized.

Smart Attachments

Attachments are becoming smarter. They have sensors and microprocessors. They adjust to different tasks automatically. This increases their effectiveness. Attachment changes are quicker and easier.

Energy Storage Solutions

Energy capacity is a key concentration. High level batteries store more power. Supercapacitors are additionally utilized. These give excess of energy when required. This is significant for high demand task.

Real-Time Data Analytics

Data analytics are integral. Real-time data improves decision-making. Performance metrics are tracked continuously. This helps in optimizing operations. Predictive analytics prevent potential issues.

Modular Designs

Modular designs are gaining traction. Components are easily swapped. This increases flexibility. Maintenance is simpler and quicker. Customization options are numerous.

Collaborative Robots

Collaborative robots are used with excavators. They assist in complex tasks. This improves efficiency and safety. Human-robot collaboration is seamless. Training for operators includes working with robots.

Blockchain for Supply Chain

Blockchain technology is enhancing supply chains. It ensures transparency and traceability. Parts and materials are tracked from source. This improves quality control. It also reduces counterfeiting.

Enhanced Training Programs

Training programs are advanced. Virtual reality simulates real-world scenarios. Augmented reality provides on-site assistance. Online training modules are comprehensive. This ensures skilled operators.

Advanced Noise Reduction

Noise reduction is significant. New materials absorb sound better. Design improvements minimize noise. This is crucial for urban environments.

Sustainable Manufacturing Processes

Manufacturing processes are more sustainable. We use energy-efficient factories. Minimize waste. We integrate recycled materials. This reduces the environmental footprint.

Conclusion

Excavators or earthmoving equipment’s in 2024 are smarter and greener. They incorporate cutting-edge technology. Efficiency, safety, and sustainability are prioritized. These advancements are transforming the construction industry.

FAQ’s

Electric excavators or earthmoving equipment’s are the future of building equipment’s.

How much electric or earthmoving equipment’s are efficient then old excavators?

Which characteristics make electric excavators or earthmoving equipment’s more helpful and useful?

Remote control excavators or earthmoving equipment’s are the real automotive monsters.

What are the latest trends in earthmoving equipment?

2 Comments