What is the Future of Automation in Fabrication?

Automation in fabrication is evolving rapidly. It promises to transform how products are made. Advanced technologies are driving these changes. Here’s a look at what the future holds.

The Rise of Automation

Automation refers to the use of technology to do tasks. In fabrication, machines and robots complete the work. This change aims to improve efficiency and precision.

Current Trends in Automation

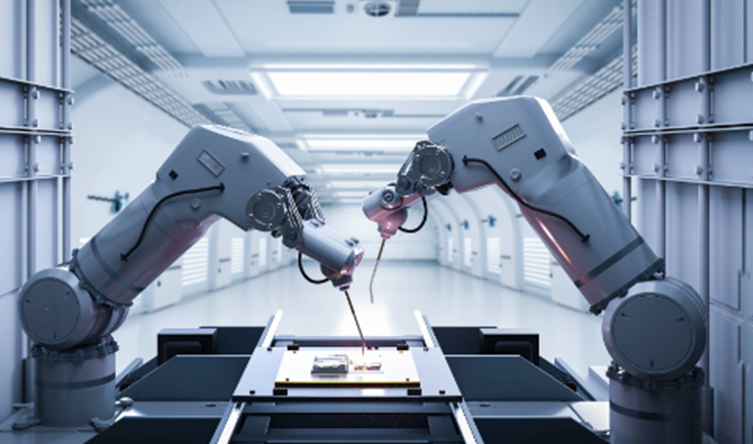

1. Increased Use of Robots

Robots are becoming more common in fabrication. They handle repetitive tasks efficiently. Robots improve consistency and reduce human error.

2. Integration of AI

Artificial Intelligence (AI) is making machines smarter. AI systems can learn and adapt. This allows for more complex and precise fabrication.

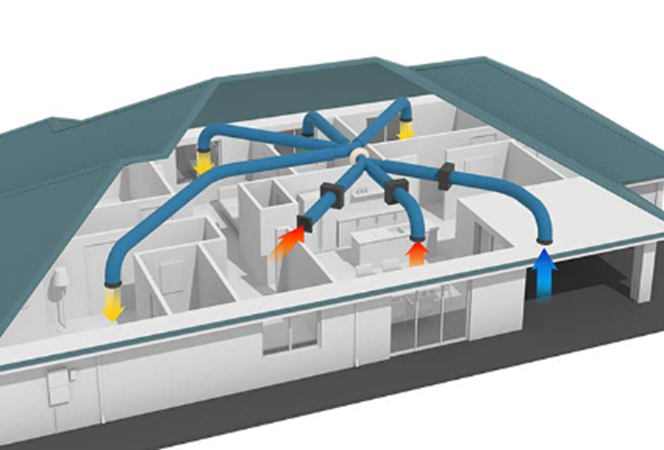

3. Advanced Sensors and IoT

Sensors and Internet of Things (IoT) technology provide real-time data. They help monitor and control fabrication processes. This improves quality and reduces downtime.

4. 3D Printing

3D printing is revolutionizing fabrication. It allows for rapid prototyping and production. Complex parts can be made quickly and cost-effectively.

5. Collaborative Robots (Cobots)

Cobots work alongside human operators. They are designed to be safe and user-friendly. Cobots enhance productivity without replacing human workers.

The Benefits of Automation

1. Improved Efficiency

Automation in fabrication accelerates the manufacturing process. Machines outclass humans in terms of both speed and duration. This leads to increased production and decreased expenses.

2. Enhanced Precision

Automated systems provide consistent and accurate results. This reduces defects and waste. High precision is crucial for complex parts.

3. Lower Labor Costs

Automation in fabrication reduces the need for manual labor. This lowers overall labor costs. However, it may require investment in technology and training.

4. Better Safety

Automated systems can handle dangerous tasks. This reduces the risk of workplace accidents. Safety is improved as machines take on hazardous jobs.

5. Flexibility and Customization

Automation allows for greater flexibility. Systems can be reprogrammed for different tasks. This enables custom and small-batch production.

Challenges Facing Automation

1. High Initial Investment

Automation can be costly to adopt. Investing in new technology and training is expensive. However, the long-term advantages frequently outweigh the costs.

2. Skill Gaps

Automation requires skilled operators and technicians. There may be a shortage of trained professionals. Ongoing training and education are necessary to fill this gap.

3. Integration Issues

It might be difficult to integrate new technology into current systems. There may be compatibility and connectivity concerns. Successful integration requires careful planning and assistance.

4. Maintenance and Downtime

Automated systems require regular maintenance. Unplanned downtime can affect productivity. Maintenance strategies must be in place to address these issues.

5. Cybersecurity Risks

Automated systems are vulnerable to cyber-attacks. Protecting sensitive data and systems is crucial. Robust cybersecurity measures are necessary to safeguard automation processes.

Future Developments in Automation

1. Enhanced Machine Learning

Machine learning will further improve automation. Systems will become more intelligent and adaptive. This will enhance decision-making and process optimization.

2. More Advanced Robotics

Robots will become more versatile and capable. They will handle a wider range of tasks. Advanced robotics will enable more complex and precise fabrication.

3. Increased Use of Blockchain

Blockchain technology will be used for data security and traceability. It will ensure transparency and reliability in fabrication processes. Blockchain will enhance trust and accountability.

4. Greater Customization with AI

AI will enable more personalized and custom fabrication. Systems will adjust to individual requirements with greater ease. Customization will become more accessible and cost-effective.

5. Sustainable Practices

Sustainability will be a key focus of future automation. Eco-friendly materials and procedures will be utilized. Automation will seek to minimize waste and energy use.

The Impact on Industries

1. Manufacturing

Automation in fabrication will improve production efficiency. This will result in faster and more efficient manufacturing procedures. The industry will profit from decreased prices and higher quality.

2. Automotive

The automobile sector will experience breakthroughs in assembly and parts manufacturing. Automation will improve precision and speed in automobile manufacture. The industry will adopt more innovative and efficient methods.

3. Aerospace

Aero-space fabrication will benefit from high-precision automation. Complex parts and assemblies will be produced with greater accuracy. Automation will support the development of advanced aerospace technologies.

4. Consumer Goods

The consumer goods industry will use automation for rapid production and customization. Automated systems will handle high-volume production efficiently. Customization options will be expanded to meet consumer demands.

5. Healthcare

In healthcare, automation will improve the production of medical devices and pharmaceuticals. Precision and consistency will be enhanced. Automation will support the development of advanced healthcare solutions.

The future of automation in fabrication looks promising. Technology advancements are resulting in greater efficiency, precision, and customization. While there are certain problems, the advantages of automation are enormous. Fabrication processes will improve in sophistication and efficiency as technology advances. Automation will play a significant role in defining the future of manufacturing and production.

FAQ’s

What advancements are expected in automation for fabrication?

How will automation impact manufacturing efficiency?

What are the potential challenges of adopting automation?

Will automation lead to job losses in fabrication?

How can companies prepare for the future of automation?