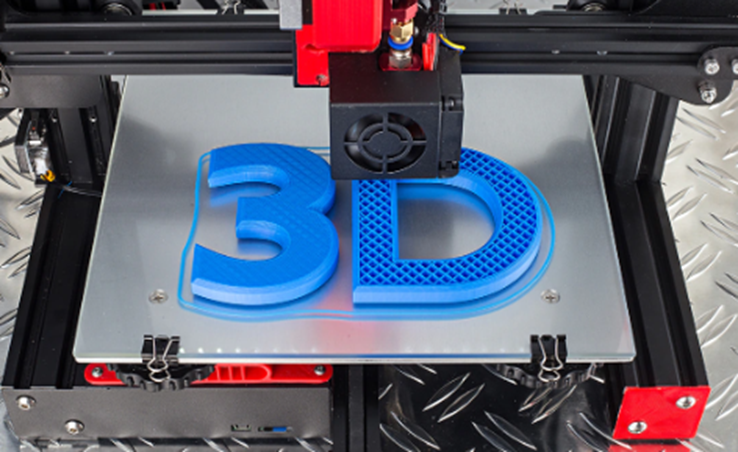

Revolutionary Applications of 3D Printing in Manufacturing

3D printing is changing the manufacturing business. It permits companies to create complex parts rapidly and proficiently. This innovation is also called additive manufacturing. It fabricates objects layer by layer, directly from computerized models. It impacts how people plan, prototype, and produce items.

Rapid Prototyping

Rapid prototyping is one of the vital purposes of 3D printing. Generally, it was tedious and costly to make prototypes. With this, makers can deliver prototypes very quickly. This considers quicker plan for designing and improvement. Engineers can test and refine their plans rapidly. This speeds up the product development process significantly.

Customized Production

Customization is one more significant advantage of 3D-printing. It permits manufacturers to make customized items at scale. In traditional manufacturing, customization is frequently expensive and wasteful. However, with this printing, everything can be tailored to special needs without additional expense. This is especially important in industries like medical services. For example, It is utilized to make custom prosthetics and inserts. Each piece is designed to flawlessly fit the person.

Complex Geometries

Complex designs that are very difficult to create with old methods; are now possible with 3D-printing. Old manufacturing techniques frequently has many restrictions when producing such complex models. It allows to create a design with both internal and external features and many other complex features with accuracy. This initiates new options in product designing. Now manufacturers are able to design those products which were not possible in the past.

Tooling and Fixtures

In this era of innovations 3D-printing is also used to create tool and fixtures for any industries. These tools play a key role in manufacturing procedures. Old methods of producing tools were so deliberate and costly. 3D-printing makes tooling production quick and cost effective. 3D printing offers more flexibility production process. Companies with 3D printing are now able to produce required tools in short time.

On-Demand Production

Creation of demanded products is becoming easier and more normal with 3D printing. Now companies can produce only needed items instead of mass producing and storing them. 3D printing reduces creation costs and lessens waste. On-demand creation allows manufacturers for rapid response to market demands. Makers can adjust to changes and produce what is required when it’s required.

Lightweight Components

3D printing is the best method to create lightweighted parts especially for aerospace and auto industries. Lightweighted parts are the best options in these industries to improve performance and fuel cost. Without compromising strength, It allows to produce lightweighted parts. In outcomes we receive effective products that use less material.

Sustainable Manufacturing

Sustainability is a developing worry in production. 3D printing offers a more practical way to deal with creation. Traditional manufacturing frequently brings about a great deal of waste, as material is taken out to make parts. However, It utilizes just the material required, lessening waste altogether. Also, It permits for the use of recycled materials, further upgrading sustainability.

Localized Manufacturing

It empowers localized assembling. Companies can set up little creation centers near their clients. This diminishes the requirement for long supply chains and transportation costs. Localized assembling likewise allows for faster delivery times. This is especially valuable in industries where speed and customization are significant.

Spare Parts Production

Producing spare parts is one more significant utilization of 3D printing. Companies can make spare parts on-request rather than keeping huge inventories. This is especially valuable for more established items where extra parts are no longer accessible. It takes into consideration the creation of these parts, broadening the life of items. It also lessens the requirement for huge extra storage spaces and related costs.

Innovation and Experimentation

It empowers development and experimentation in assembling. Designers and engineers can test groundbreaking thoughts rapidly and cost-effectively This encourages a culture of development inside companies. The ability to experiment without significant expenses prompts the advancement of new items and arrangements. This is driving the manufacturing industry forward and leading to exciting new possibilities.

Conclusion

Benefits of 3D printing are vast. From rapid prototyping to sustainable production is are the impacts or results of 3D printing. It is transforming production and allows more customization, technology and efficiency. Companies with 3D printing technology will be on the leading position in future. Evolving of 3D printing will result only in manufacturing growth.

FAQ’s

What is 3D printing in manufacturing?

How does 3D printing benefit rapid prototyping?

Can 3D printing be used for mass production?

Is 3D printing cost-effective for manufacturing? Which industries are benefiting most from 3D printing?