How to Manufacture Smart Materials: A Step-by-Step Guide

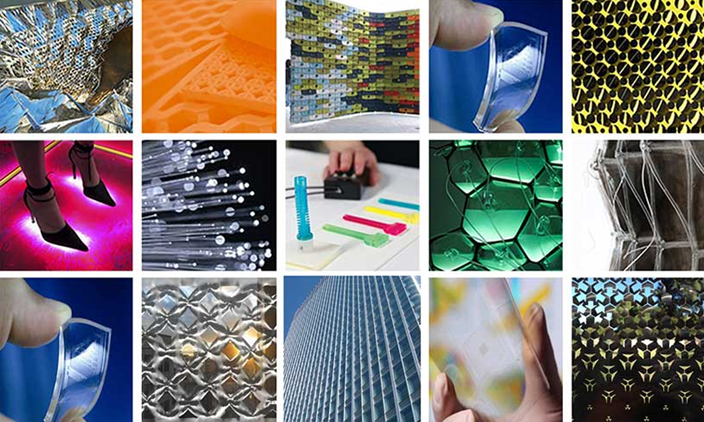

Smart materials respond to their surroundings. They adjust to a variety of stimuli, including temperature and pressure. These materials are fabricated using advanced methods. Each method is specific to the type of smart material.

Types of Smart Materials

There are different sorts of smart materials. These include piezoelectric, shape-memory, and electrochromic materials. Each class serves a certain purpose. The fabrication technique also differs.

Piezoelectric Materials

Applying pressure to piezoelectric materials generates electricity. Ceramics and quartz are common examples. They are utilized in sensors, actuators, and medical equipment.

Shape-Memory Alloys

Shape-memory alloys return to their original shape after deformation. They are used in medical stents, eyeglass frames, and robotics.

Electrochromic Materials

Electrochromic materials change color with electrical charge. They are used in smart windows and displays.

Fabrication Process for Piezoelectric Materials

Piezoelectric materials require precise control during fabrication. First, raw materials are carefully selected. These materials are typically ceramics or polymers.

Step 1: Material Preparation

The first step is to mix the raw materials. This creates a homogeneous blend. Any impurities are removed during this stage.

Step 2: Shaping

Next, they shape the material into thin films or blocks through extrusion, casting, or pressing.

Step 3: Polarization

The material undergoes polarization. An electric field is applied, aligning the dipoles. This step enhances its piezoelectric properties.

Step 4: Sintering

They then heat the developed material in a process known as sintering. It reinforces the material and completes its structure.

Step 5: Testing

Once fabricated, the material undergoes rigorous testing. This ensures its piezoelectric response is optimal.

Fabrication Process for Shape-Memory Alloys

Manufacturers usually make shape-memory alloys from nickel and titanium. They fabricate these materials through a series of controlled processes.

Step 1: Alloy Composition

The first stage comprises alloy composition. Nickel and titanium are combined at specific ratios. This guarantees that the alloy has shape-memory qualities.

Step 2: Melting and Casting

They melt the alloy at high temperatures and then cast it into desired shapes.

Step 3: Thermomechanical Processing

Next, the alloy undergoes thermomechanical processing. This involves heating and deforming the material.

Step 4: Annealing

Annealing is a key step in the fabrication process. The alloy is heated and slowly cooled. This locks in its shape-memory behavior.

Step 5: Training

They “train” the alloy to remember specific shapes by repeatedly deforming and heating the material.

Step 6: Testing and Quality Control

Finally, the alloy undergoes testing. Engineers ensure it returns to its original shape after deformation.

Fabrication Process for Electrochromic Materials

They widely use electrochromic materials in smart windows. Their fabrication involves several key steps.

Step 1: Material Selection

The first step is selecting the appropriate electrochromic materials. Common materials include tungsten oxide and nickel oxide.

Step 2: Thin Film Deposition

They apply the materials to a substrate as thin films using processes such as sputtering or chemical vapor deposition.

Step 3: Layering

Multiple layers are applied to the substrate. These layers include an electrolyte, electrodes, and electrochromic material.

Step 4: Sealing

The layers are sealed to avoid contamination. This extends the life of the electrochromic material.

Step 5: Testing

They test the final product for color-changing efficiency. It must respond quickly to electrical charges.

Advanced Fabrication Techniques

Many smart materials use advanced fabrication techniques. These include 3D printing, nanotechnology, and laser processing. Such techniques allow for more precise control.

3D Printing

They use 3D printing to create custom shapes, printing smart materials layer by layer. This allows for complex geometries.

Nanotechnology

They use nanotechnology to manipulate materials at the atomic level. This enhances their properties and performance.

Laser Processing

Laser processing uses focused light to shape materials. This is important for generating exact patterns.

Challenges in Fabrication

Fabricating smart materials is not without drawbacks. One key challenge is maintaining uniformity. Variations in material composition can have an impact on performance.

Cost of Materials

Smart materials often involve expensive raw materials. This increases the cost of production.

Complex Fabrication Processes

The fabrication method for smart materials can be difficult. It involves particular equipment and experience.

Testing and Quality Control

Testing smart materials is critical but time-consuming. They must thoroughly test every batch for performance.

Applications of Smart Materials

Smart materials have applications in many industries. These include aerospace, healthcare, and consumer electronics.

Aerospace

In aerospace, smart materials are used in aircraft sensors. They help detect changes in pressure or temperature.

Healthcare

In healthcare, shape-memory alloys are used in surgical devices. They provide minimally invasive solutions.

Consumer Electronics

They use smart materials in consumer electronics. They find electrochromic materials in smart displays and wearables.

Future of Smart Materials Fabrication

The future of smart materials is promising. Researchers are developing new methods to simplify fabrication.

Automated Processes

Automation is expected to streamline the fabrication process. This will reduce costs and improve efficiency.

Sustainability

Researchers are exploring eco-friendly materials for smart material production. This will make fabrication more sustainable.

Improved Performance

Advances in nanotechnology will improve the performance of smart materials. They will become more responsive and durable.

Conclusion

Smart materials are transforming numerous industries. Their manufacture necessitates meticulous attention to detail. Each type of material, from piezoelectric to shape-memory alloys, goes through its own set of operations. Advanced techniques, such as 3D printing and nanotechnology, are improving fabrication precision. Despite the hurdles, the future of smart materials is promising.

FAQ’s

What are the main types of smart materials?

What is the first step in fabricating smart materials?

How do manufacturers fabricate piezoelectric materials?

What techniques do manufacturers use to fabricate shape-memory alloys?

What advanced methods do manufacturers use in smart material fabrication?