Laser Cutting in the Modern World: Types and Applications

Laser cutting is a precise fabrication process. It uses a focused laser beam. The beam cuts materials accurately and efficiently.

Basics of Laser-Cutting

Laser-cutting starts with a design file. You create the file using CAD software and then send the design to the laser cutter.

How Laser-Cutting Works

A highly focused beam generates and focuses on the material. This laser beam melts and vaporizes the targeted material. It results in a clean cut.

Cutting Different Materials

Laser-cutting works on various materials. It cuts metals, plastics, and wood. It also works on fabrics and paper.

Components of a Laser Cutter

A laser cutter has key components. The laser source generates the beam. The focusing lens sharpens the beam. The cutting head directs the beam. The worktable holds the material.

Material Preparation

Prepare the materials for cutting by cleaning and placing them on the worktable. Then, calibrate the laser cutter.

Laser-Cutting Parameters

Several parameters affect cutting quality. These include laser power, speed, and focus. The right settings ensure precise cuts.

Laser-Cutting Techniques

- There are different cutting techniques. Fusion cutting uses an assist gas. The gas removes molten material.

- Flame cutting is another technique. It uses oxygen as the assist gas. It is used for thicker materials.

Types of Lasers-Cutting Machines

1. CO2 Laser-Cutting

CO2 lasers are versatile. They cut wood, acrylic, and leather. They are used in many industries.

2. Fiber Laser-Cutting

Fiber lasers are powerful. They cut metals like steel and aluminum. They are efficient and fast.

Advantages of Laser-Cutting

Laser-cutting offers various benefits like high accuracy and precision. It makes clean and smooth ends. Laser cutting is a fast and efficient process. It can cut even complex shapes. It lessens material waste.

Applications of Laser Cutting

Laser cutting is used in many industries. It creates parts and components in manufacturing. It designs fabrics and patterns in fashion.

In automotive, it cuts body parts and frames. In electronics, it cuts circuit boards.

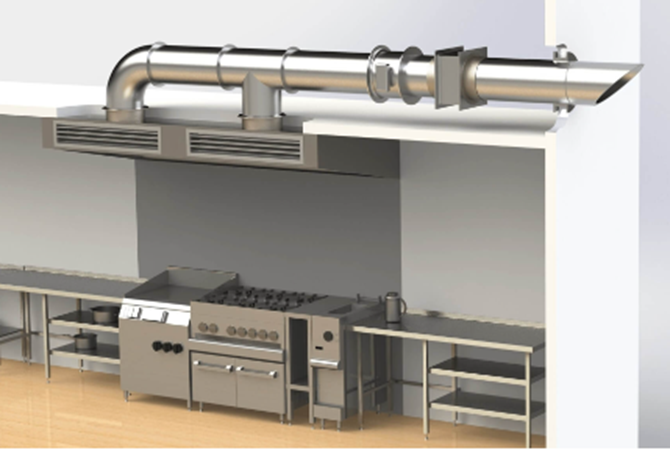

Safety Considerations

Safety is laser cutting is a vital component of whole process. Proper ventilation is required and protective eyewear is essential.

Operators must be highly trained. Safety interlocks protect from accidents.

Challenges of Laser Cutting

Setup expenses can be the main challenge for laser cutting. It needs maintenance and adjustment.

Thick materials can be tough to cut. Reflective materials can cause problems.

Future of Laser Cutting

Laser cutting technology is advancing. New lasers are more powerful. They are also more efficient.

Automation is being integrated. This increases productivity. New materials are being explored.

Conclusion

Laser cutting is a precise and versatile process. It uses a focused laser beam. It cuts various materials accurately. Different techniques and lasers are used. It offers many advantages. Its applications are vast and diverse. Safety and maintenance are important. The future holds exciting progressions. Laser cutting continues to progress. Its potential is huge.