The Process of 3D Printing in Material Fabrication: Materials You Need to Know

Introduction

3D printing constructs objects layer by layer. It begins with a computerized model. Computer-aided design (CAD) software creates the model. This computerized record guides the printer. The printer follows exact guidelines. It deposits material layer by layer. Each layer is slight and exact.

Process

The process begins with the first layer. The printer deposits material on the base. After the first layer, it continues upward. Each new layer bonds to the previous one. This builds the object gradually. The process repeats until completion.

Types

There are various types of 3D-printing. Some types are given below.

Fused Deposition Modeling (FDM) is an ordinary type. FDM make use of thermoplastic filaments. The machine melts and squeezes out the filament.It solidifies upon cooling.

Stereolithography (SLA) is another method. SLA uses a liquid gum. UV light dries the gum.

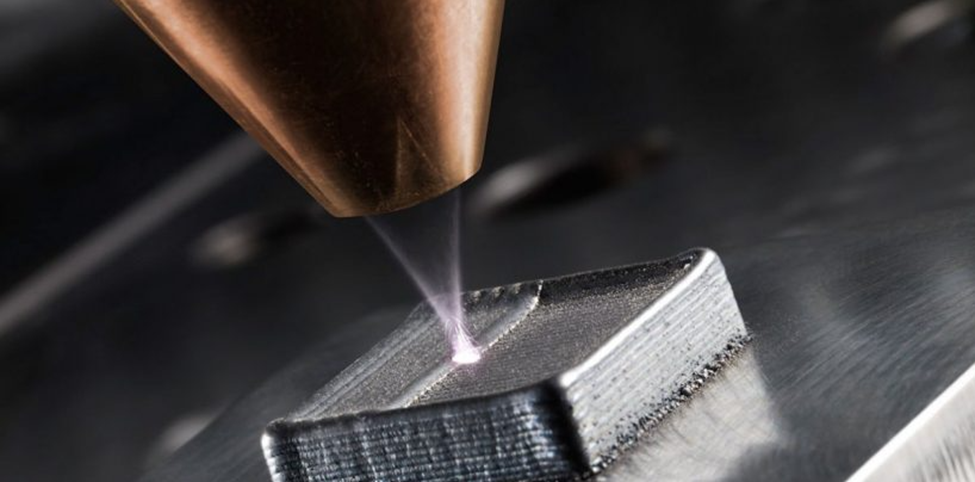

Selective Laser Sintering (SLS) uses powdered materials. A laser fuses the powder particles.

Materials Used in 3D Printing

Plastics are general materials in 3D printing. PLA is a usual plastic. It is recyclable and simple to use. ABS is another popular plastic. It is strong and durable. Nylon is also used. It is elastic and tough.

Metals

Metals can likewise be 3D printed. Stainless steel is a typical decision. It is solid and corrosion-resistant. They utilize titanium for high-strength applications. Aluminum is lightweight and flexible. They also utilize valuable metals like gold. They use them for gems and art.

Ceramics

Ceramics are another option. They are used for their heat resistance. Ceramic 3D-printing is precise. It creates detailed objects.

Composites

They also use composites. They combine different materials. This enhances their properties. Carbon fiber composites are strong and light. Glass fiber composites are tough and durable.

Biomaterials in 3D Printing

It also uses biomaterials. They use these in medical applications.They create implants and prosthetics. Bioprinting uses living cells. It creates tissues and organs.

Food in 3D Printing

Food can be 3D printed too. Chocolate is a common choice. Sugar and dough are also used. This allows for custom shapes.

Applications of 3D-Printing

On the basis of its characteristics; Businesses use 3D-printing as a multipurpose technique.

It makes implants and prosthetics in healthcare business.

Shapes lightweight elements in aerospace business.

Designs exclusive clothing in fashion.

Makes building elements in construction business.

It assists learning and creativity in education.

Advantages of 3D-Printing

3D-printing offers many advantages. Allows for rapid prototyping. Reduces waste by using exact amounts. It enables custom designs and complex geometries. It is cost-effective for small production runs.

Challenges of 3D-Printing

3D-printing also faces difficulties. The materials can be costly. Large items can delay the procedure. The final product might require post-handling. There are also restrictions in material strength.

Future of 3D Printing

3D-printing keeps on developing. New materials are being created. The innovation is becoming to be quicker and more productive. It is being scattered into many industries. Its true potential is immense and energizing.

Conclusion

3D printing is developing material creation. It fabricates objects layer by layer. This considers complex plans. Numerous materials can be utilized. Plastics, metals, ceramics, and many more. Every material has extraordinary properties. These are outfit for various purposes. 3D printing keeps on developing. Its future holds tremendous potential.

FAQ’s

How the 3D-Printing Processes?

What are the main types of 3D Printing?

Which materials are used in 3D Printing?

What are the applications of 3D Printing?

Write some advantages of 3D Printing.

Which type of Challenges 3D Printing is facing in moder world?

What is the future of 3D Printing?